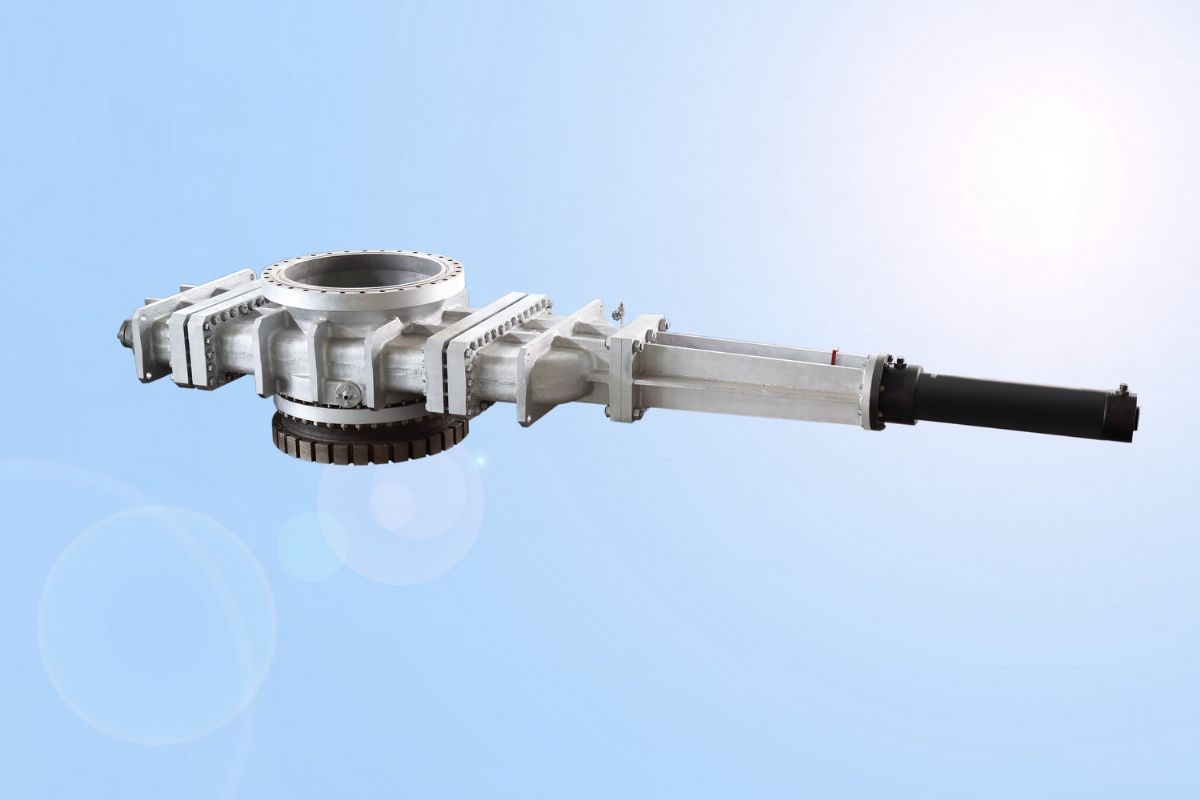

Coke drum top/bottom unheading valve

Coke drum bottom unheading valve and top beheading valve are mainly applicable to the bottom and top of the coke drum in the delayed coking unit of the refinery, fully meeting the complex working conditions of high and low temperature frequent alternation and gas-liquid-solid mixed fluid in the coking unit. They can also be extended to the burnt gate valve of the ethylene unit, the gate valve of the coal pipeline of the coal chemical plant and other stations containing solid fluid or high and low temperature alternating.

1. Technical Parameter

|

Design Temperature

|

550℃

|

Operating temperature

|

500℃

|

|

Design pressure

|

1.0MPa

|

Operating Pressure

|

0.5MPa

|

|

Explosion proof level

|

dⅡCT4

|

leakage rate

|

Zero leakage of medium

|

|

Nominal diameter of coke drum bottom unheading valve

|

DN1500

|

Full stroke time of coke drum bottom unheading valve

|

≤5min

|

|

Nominal diameter of coke drum top beheading valve

|

DN900

|

Full stroke time of coke drum top beheading valve

|

≤3min

|

2. Product Characteristics

◆The valve adopts a parallel single disc gate valve structure as a whole.

◆The sealing structure adopts the floating bimetal hard seal+steam auxiliary seal technology to achieve zero leakage of the medium, and at the same time, it can absorb thermal expansion during the high and low temperature alternation.

◆Designed with a coke shielding cover, effectively preventing coke powder from entering the valve chamber.

◆The valve disc is made of 25Cr2MoVA high-strength alloy steel. After surface grinding, it is subjected to glow ion nitriding, with a surface hardness of 650HV and a nitriding layer thickness of 0.5mm, resulting in a long service life.

◆The orifice plate is made of chromium molybdenum steel forgings, with 802 hard alloy surfacing on the sealing surface, surface hardness=40HRC, surfacing thickness=3mm, and good wear resistance.

◆Equipped with a high-power electro-hydraulic actuator with interlocking function, achieving safe and reliable valve opening and closing.

◆The upper and lower valve ports are designed to be detachable and can be used as maintenance ports during maintenance, making maintenance and replacement of sealing components more flexible.

◆Use ANSYS software to conduct finite element analysis and optimization design on the valve body and valve bonnet, ensuring that the components have good strength and rigidity under actual working conditions of pressure and temperature.

★Introduction of achievements

◆Coke drum bottom unheading valve and top beheading valve have been applied in Lanzhou Petrochemical Company, Karamay Petrochemical Company, Jinzhou Petrochemical Company and other units, with smooth opening and closing and stable operation.

◆The coke drum bottom unheading valve won the third prize of the 2010 CNPC Science and Technology Progress Award.

◆A total of 5 authorized patents have been obtained for Coke drum bottom unheading valve and top beheading valve.

◆One enterprise standard of CNPC "Q/SY1708-2014 General technology Conditions for Coke drum Bottom Unheading/ top beheading Valves for Delayed Coking" was formulated.

|